Flashback to late August:

After replacing the wheels on my RC10 gold pan buggy, it didn’t handle very well. Considering the fact that the front wheels rubbed on the front a-arm at full steering travel, that should not have been surprising. But I wanted to try reducing the steering travel to avoid rubbing, and see if that helped.

Unfortunately this didn’t work. The steering linkage was plagued with problems. The car had a wider turning radius in one direction than the other, the servo struggled, and there was a lot of play in the linkage.

After looking at the steering linkage enough times, I realized it pretty much sucked. Plastic bell cranks ran directly on threaded screws for pivots without bearings; the servo saver was sloppy; and it had a bent wire linkage to the servo instead of a ball and socket linkage.

After doing some research at rc10talk.com, I learned that replacing the steering linkage with one that used bearings was common. Most of the bell cranks that were used Back In The Day are no longer available. However, Traxxas makes a bell crank set that’s a perfect fit. Sweet! Okay, well not perfect, but close enough.

As outlined here, you need to make shims to fit between the inside of a 3/16 bearing, and the 8-32 screw used as a pivot on the RC10. I used some of the #8 washer/spacers used on the rear wheels, to ensure that the bearings spun freely instead of rubbing on the chassis. Once you do this, the rest is easy: install the bell cranks and turnbuckles, and you’re good to go with identical steering geometry to the original.

This helped a lot: steering was faster and more responsive, and with the better turnbuckle linkage I could tune it a lot more finely than it was before. Unfortunately there still just wasn’t enough travel, so I was still stuck.

I wanted to get new front hubs with more caster. The original car has 25° for the shock travel angle, but the hubs push caster back to 10°. I wanted to try 25° of caster, so I bought some RC10B4 caster blocks and hub carriers and associated gubbins. Unfortunately I got the wrong king pins, and couldn’t assemble it.

Flashforward to late September:

|

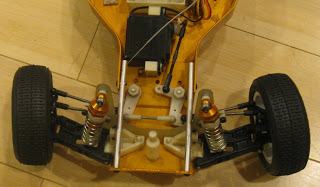

| RC10 with Traxxas bell cranks and wide track arms |

I sat around not doing anything with the RC10 for a long time, but then I needed to order a replacement part for my Losi XXX-SCB. So, I added my missing king pin (and screws) onto the order. A-Main hobbies also carried some original RC10 swept-back front A arms, the “wide track” version in black; so I added those to the order as well.

Oh, I should also really replace all the transmission bushings with bearings, so let’s just throw those onto the order as well…

So on Tuesday night and Wednesday, I put it all the new parts on and rebuilt the shocks with heavier oil. Here’s the result.

I had to remove the front anti-roll bar, because there is no mounting point for it on the wide track A-arms. I calculated appropriate turnbuckle lengths to maintain the original geometry by extrapolating based on the increased A-arm length, but I expected to have to tweak them after driving it a bit. Now, at extreme steering angles, the inside of the plastic hub is the first part to hit the A-arm; but at that point, you have plenty of turning going on, so it’s not a problem.

The shocks have never been completely disassembled and rebuilt, and they’re showing some wear inside. It’s not ideal, but I’m going to live with them for now. I completely cleaned the transmission parts using Simple Green in an ultrasonic cleaner, removed the bushings, and reassembled everything with the bearings. Once every 30 years isn’t too often, is it?

On Wednesday night, I brought the car to the track and tried it out. It worked a lot better than I expected: handling was great without me having to tweak anything at all. I ran it through 2 battery packs, as much as I ran the Losi-SCB last night. Apparently I’ve already bent one of the camber links, though; I guess I need Real Turnbuckles instead of threaded rod.

There was one problematic incident: I popped an E-clip on the transmission, and it blew the “bearing adapter”out the left side of the car. That’s weird. There seems to be more slop on this shaft than it had with the bushings. I used a new E-clip there, and it was fine for the rest of the night. Consulting the assembly instructions didn’t show me any parts I was missing, so maybe the bearings aren’t the same dimension as the bushings they replaced.

Overall, I am now very happy with the way this car handles, indoors at least. Unfortunately, whenever you pick the lowest hanging fruit, there’s always another one: it’s really slow, especially during acceleration. So now I’m thinking I might need to look into a “stock” (17.5 turn) brushless motor setup for it, to replace the brushed system it has now. But I’m going to start by going to the J&C Hobbies flea market scheduled for next Sunday to see if I can find anything fun there.

Frank broke a part on his equally vintage Kyosho Optima on Wednesday night. Don’t replace it! It’s a slippery slope, and a totally inefficient way to get a running buggy. At this point it’s almost as easy for me to list the parts I haven’t replaced, than those I have. But several modifications ago I decided to “embrace the project” since it really is at least as fun as driving the resulting car.